Tuning Myths and Facts

Tuning surprisingly has become a contentious issue. Because of the readily available tools, and safety margin of modern engine systems, it has become a quick way for someone to turn a quick profit and do the classic “sell and dump” technique of ignoring customers who aren’t happy in one way or the other (usually when they go to the dyno or look at knock counts), or worse yet, had severe engine damage as a result. We then get those customers knocking on our door, asking to have their project salvaged. After all without a good tune, what use are the tens of thousands that some of these cars have in motors and race chassis. Initially we hear they went to the cheaper tuner because they hear on the forums: “All tuners are equally good, I made xx amount of HP and the car feels good.” This is the fallacy that they are hoping you subscribe to, and they know that 75% of the time the customer may not notice. However, as time goes by, many do. Though many of these customers are reluctant to share the negative stories and offending the previous tuner or don’t want to appear duped, we see the results of this frequently. And before you ask, we will not mention names.

Before we go any further it is important that one understand some things about tuning. It is not a secret art of any kind, and there is no magic. To really excel at this it is simply a matter of hard work, painstaking analysis, and many hours on the dyno. If they claim to do something secretive outside of fuel, timing, or cam timing; they are selling snake oil. An engine makes power from the combustion process. You simply cannot effect that with anything except the big 3 below, 4 in the case of Direct Injection engines.

- Fuel

- Timing

- Cam Timing

- Direct Injection Timing (if equipped)

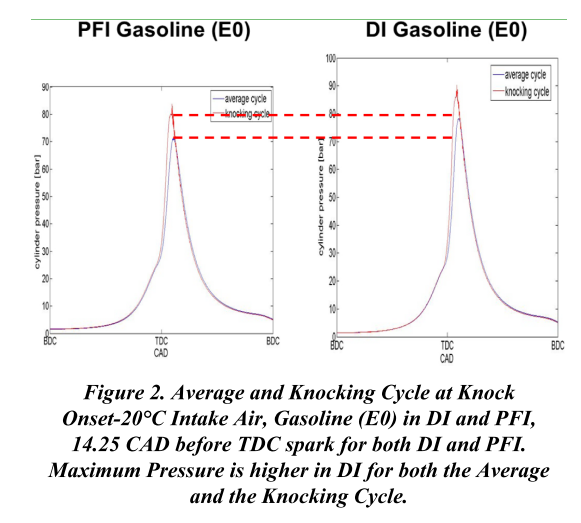

Imagine this, the rod and piston assembly make power by moving downwards. Each stroke is a fresh start, so nothing at 3500 RPM affects 4500 RPM. To make that piston push harder you have to create the highest cylinder pressure while it is moving downwards. Any earlier and you have what is called “knock.” This creates an abnormally high pressure while the piston is moving upwards. You not only lose power, but it will damage the motor eventually. So how do we create this condition of peak pressure without damaging the vehicle? You have to tiptoe the fine line, but it is not just a matter of throwing timing or fuel at the engine.

Lets take 1, fuel. Gasoline engines make best power at around 13 AFR normally aspirated, this is about .88 lambda. At this point there is just so much fuel and air that the explosion will release the most amount of energy in the power making stroke of the piston. That is, the distance traveled by the piston. If you make the mixture leaner you’ll get better efficiency, but the explosion will not be stable and will be very prone to knock. If you make it too rich, the burn time will be long, and due to the burn time being longer, the energy released will not translate to more horsepower. Burning more fuel does not equal to generating more power when the airflow is the same–you need both to increase and remain in the correct proportion. AFR also affects what timing you will need to run. The less stable the mix, the less timing advance it will need to propagate.

Now on to number 2, timing advance. Ignition timing works as follows: It takes a few milliseconds for the flame front to propagate from the time the spark plug fires. Instead of ms, lets use degrees of crank angle rotation.

So if you fire the plug when the piston is closest to the spark plug (top dead center, or TDC), the result is by the time the flamefront moves towards the piston and creates peak cylinder pressure, the piston has actually already traveled more than 20-25 degrees (as much as 30+ on some motors, as few as <10 in others). The result is that the piston is already pretty far down the bore, and now that power is being used much less efficiently. Remember Boyle’s law (PV = k); pressure is directly proportional to volume. So if you make that explosion with the piston at TDC when the cylinder volume is smallest, you’ll get much more power than making that explosion when the piston is half way down the bore, when you have much more volume for the expanding gasses to take up.

Cam timing, our 3rd point, is equally relevant. With modern DOHC heads, variable intake and exhaust cams (and duration/lift with some more advanced systems such as VTEC/VVEL), you can control the RPMs at which the motor is most efficient, expressed as Volumetric Efficiency, or VE. When you open the intake valves so the motor can “breathe in,” there are often gains to be had by simultaneously opening up the exhaust valves. Time it right, and it does not suck up any exhaust gas, but allows for a more uninterrupted and fluid movement of air. Too much overlap, and you will suck up the exhaust gasses back into the cylinder, creating an recirculating effect, that OEMs will use to eliminate EGR valves altogether, since they serve the same exact function.

Setting the cams correctly is far from simple. Various RPMs and load ranges dictate different amounts of overlap, and exactly where in the combustion cycle this overlap should occur. How do you find out that point? You never truly do. After many hours of testing on a dyno you will get incredibly close though. The trick here is that the closer you get to creating those peak pressures and ideal flow, the closer you approach to the knock threshold. So one has to be very methodical about whether to make the power from leaner AFRs, more advanced timing, or ideal cam timing.

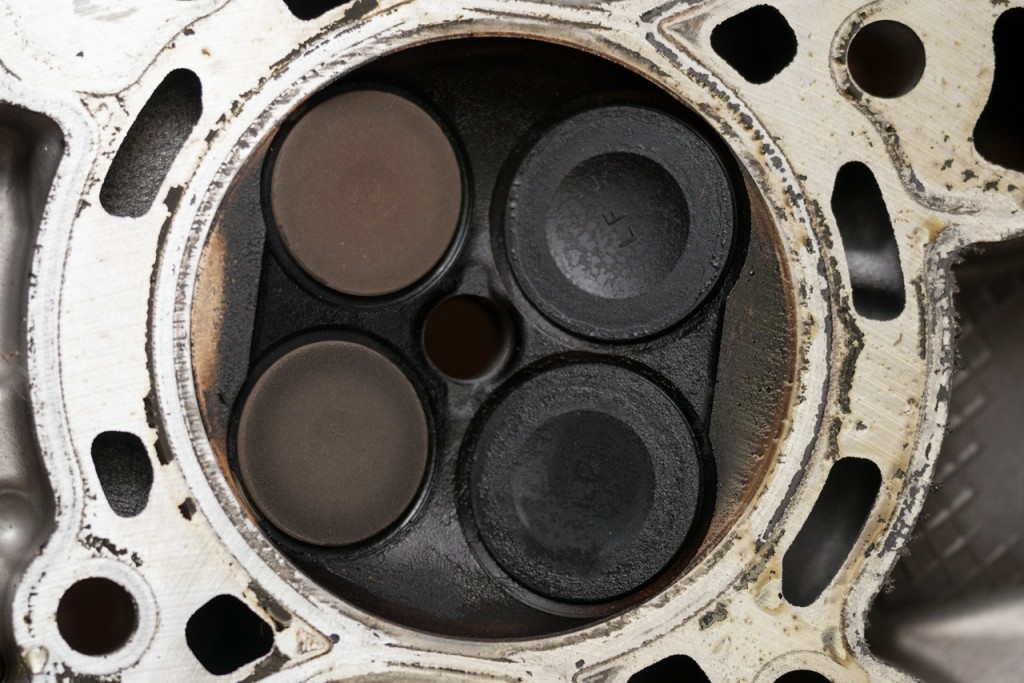

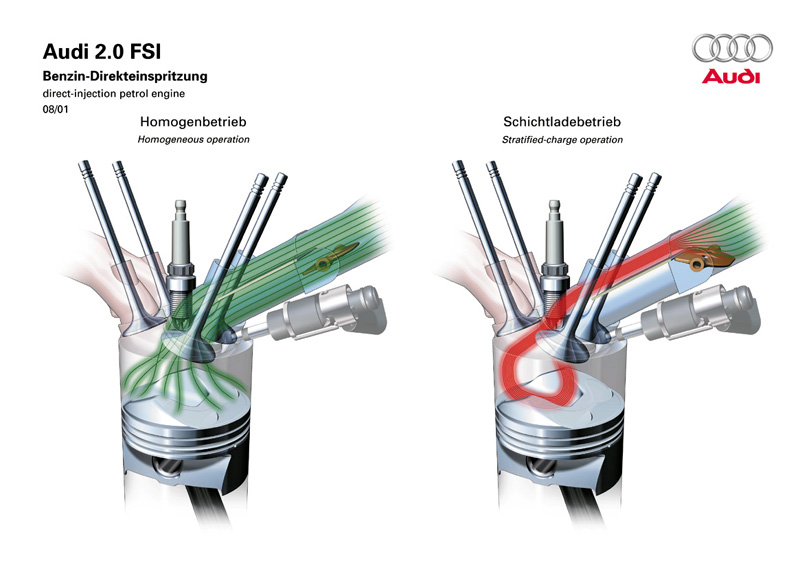

The last item here is direct injection (DI) timing. DI timing dictates when the fuel injector begins to spray fuel into the bore. Before and OEM manufacturer puts these systems out there they do the painfully painstaking process of identifying how hard, how long, and at what angle to spray that fuel mixture. The angle is then fixed from the factory (injector placement), the timing of the squirt is programmed in the ECU, and the duration is a function of the requested pulsewidth (fuel requirement). When you tweak these parameters you have to be mindful of the effects. The factory has set the car up to use either a stratified charge, or an homogenous charge. Sometimes a bit of both. The homogenous charge is what has been in production for a hundred years or so, uncontrolled squirting of fuel that mixes to form a mixture. A stratified charge on the other hand, is much more controlled and essentially forms a ball that when ignites, distributes pressure in a way that is much more controlled, and importantly, much less prone to knock.

When you alter the spray pattern of the fuel, you risk several things. All of which not only compromise the loss of the stratified charge, but have other undesirable effects. Increase the opening time too much and it will simply squirt fuel past the combustion point. If that happens you’ll see falsely rich AFRs even though when the combustion event was peaking the AFRs were quite lean. Some increase the pressure at the injector to get the fuel in quicker, but this too has consequences. Too much, and you overshoot the dish of the piston and wash down the cylinder walls. Yes, you’ll see better AFRs, but the combustion event itself was hardly ideal.

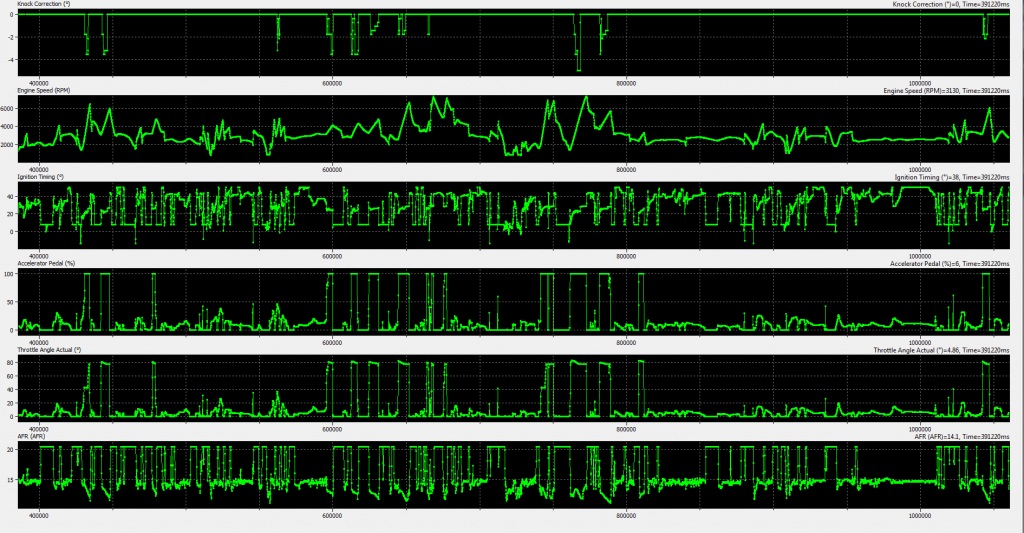

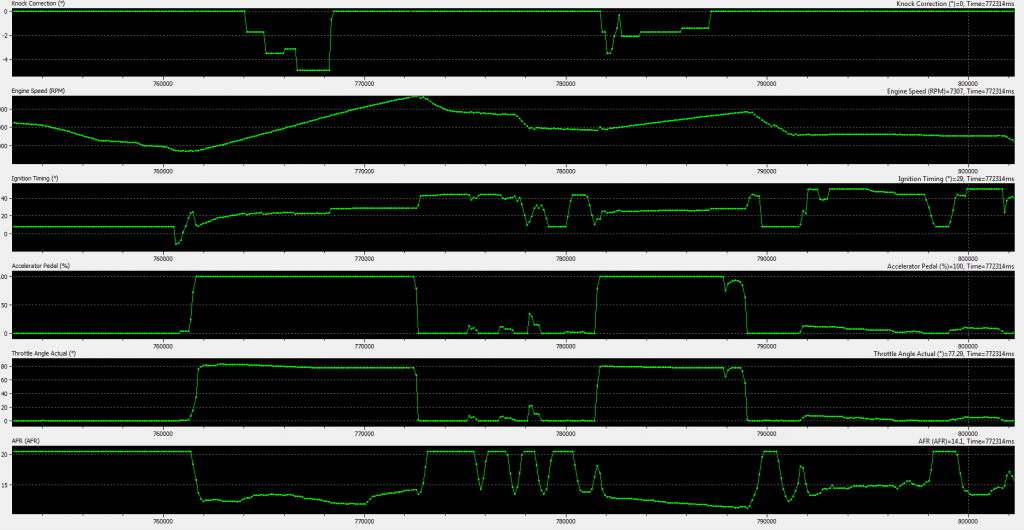

While altering all of the above can give more power, one has to be very judicious in doing so. Throughout the life of the engine, there are other forces at work that the engine ECU will not always be able to counter. Sensor drift where O2 sensors start to shift their output, reduced efficiency of the catalytic converters, air filters, carbon buildup on the motor, spark plugs widening the gap from wear, and most of all production variance; you simply can’t just crank it up blindly. This is why we have always insisted on reviewing all of the tunes with datalogs and sent revisions. Though others may offer the same service, you’re most often going to hear “it’s good!” when they simply got your hard earned money and have new customers to get to. We know this field, and we charge more because we refuse to do that and compromise the quality of our tunes. Worse yet, some of these folks have countered that their tunes are just that good right off the bat from the first revision–this last one is particularly bad. We see identical cars with identical parts vary by as much as 8% on normally aspirated cars, 25% or more on forced induction. This is why all of our tunes factor this in, and anything less is just asking for trouble. Little things like heat dissipation, knock sensor placement, manifold and fuel rail design; all can conspire against the tuner. In many cases there may be a problematic cylinder that knocks before others, and while advancing the timing still makes more overall power, that one cylinder may be the one that is knocking severely and causes engine damage. When dyno tuning, the rule of thumb is to get to peak torque, and back it down a couple of degrees. Even more if used on a track. So even though you maybe able to get more power, you have to be informed and aware of the risks. 9 times out of 10 it is a non-issue, except when you’re the 10th one. Careful review of datalogs, dyno data, and listening to the car are what it takes to assure a safe and good performing tune.

Leave a Reply

You must be logged in to post a comment.